Sunflow patented polyisocyanurate insulated foam wall panels are the highest performing proprietary structural panels on the market. Resistant to weathering, moisture and pests, Sunflow panels are durable, lightweight – making them easier to transport and install, and energy efficient.

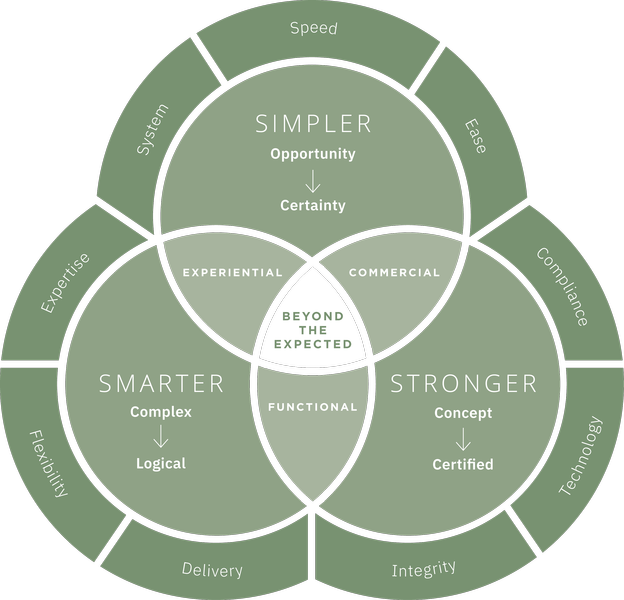

SIMPLER. SMARTER. STRONGER.

Sunflow Difference

Our System

in Motion

Watch how our innovative system seamlessly comes together.

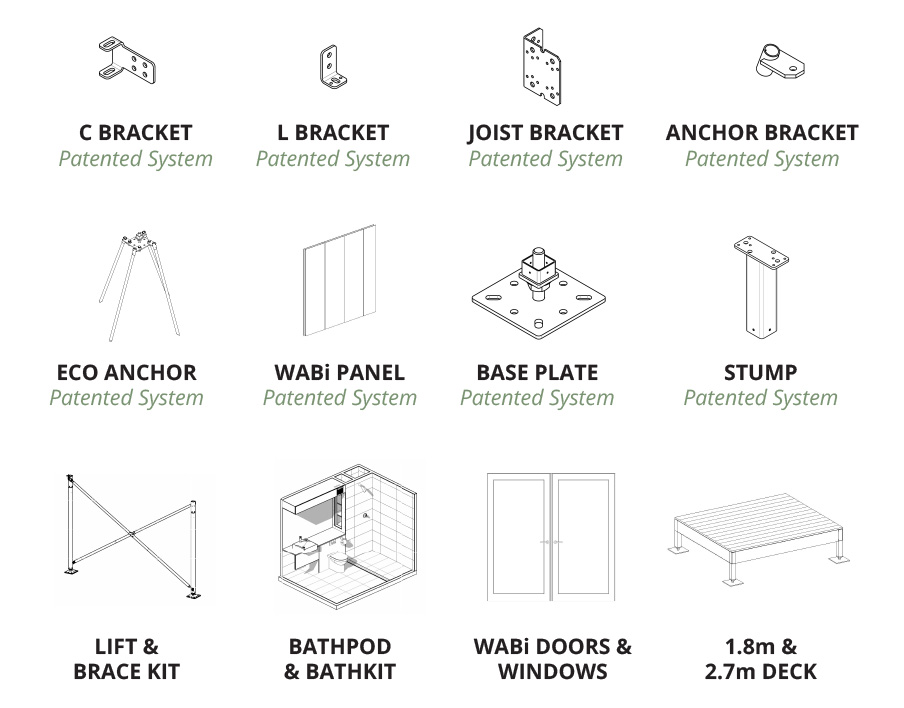

Key Parts

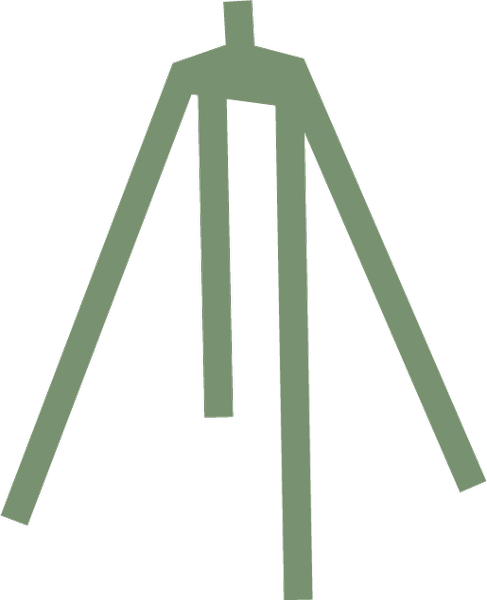

Eco Anchor

The Eco Anchor system allows our cabins to be installed with ease in remote, undulating environments, without the use of concrete. It works by driving the four drive rods into the ground using a pneumatic hammer.*Patented

Sunflow Panels

Our patented Sunflow panels (polyisocyanurate insulated foam wall panels) are the highest performing proprietary structural insulated panels on the market.

Galvanised Steel

Sunflow uses a galvanised steel framework, making it extremely robust and naturally termite, mold, rust, rodent and mildew resistant. The steel frame is endlessly recyclable and 100% non-toxic.

Bathpods

Bathpods are prefabricated in a controlled environment to ensure workmanship meets the highest standards, the pods can reduce on-site installation time from months to a matter of hours.

Sunflow Windows

Sunflow Windows in Fremantle WA, manufacture all glass doors and windows using Vantage by AWC Window Systems. Sunflow Windows have multiple glazing and frame options.

Finishes

To provide each client with a project tailored to their design needs, we have a variety of options to choose from to customise each component of the Sunflow structure.Sum of Parts

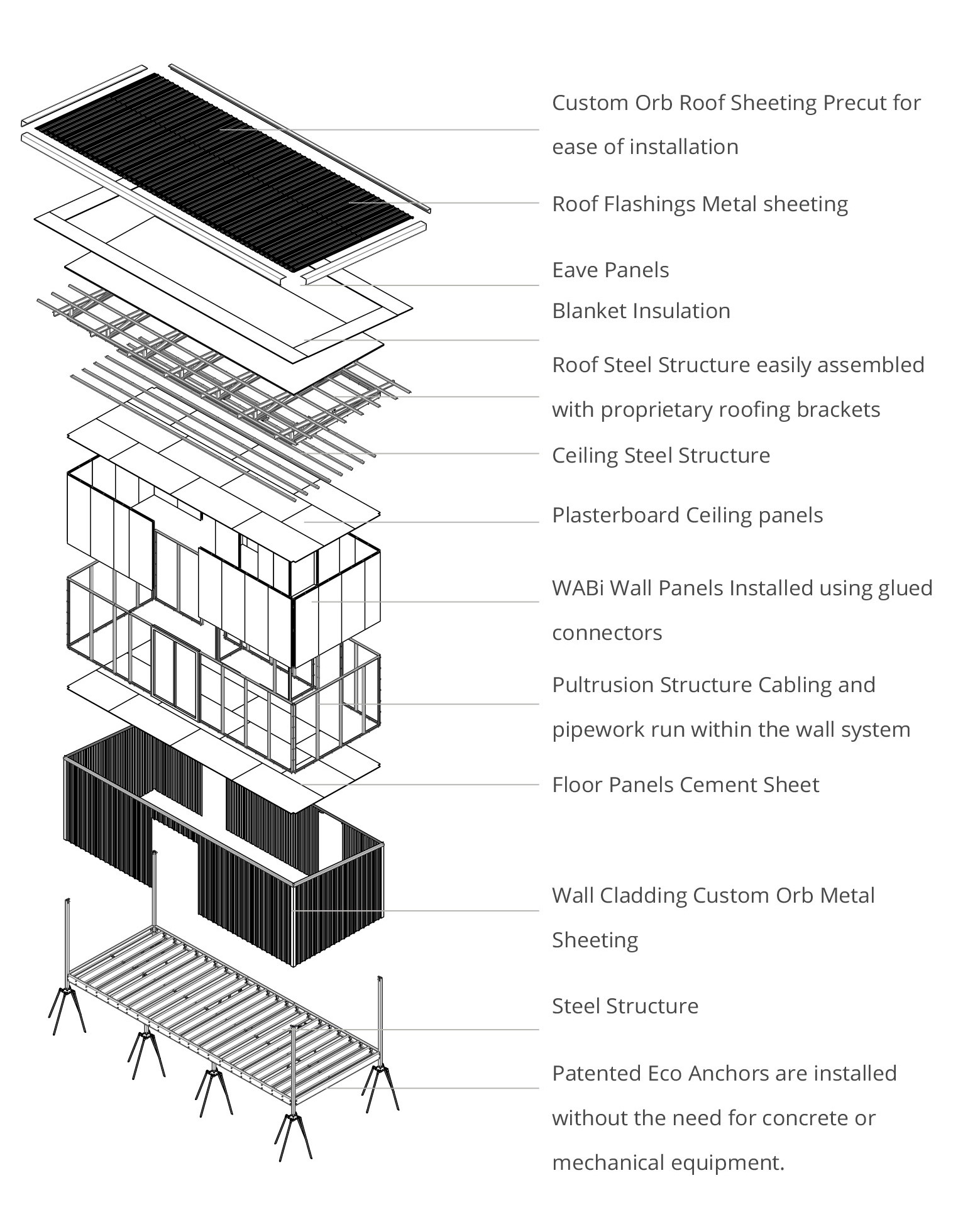

We like to think of our system like a flat pack. Using prefabricated components that are manufactured and transported separately and built together on site; using our customised installation assembly drawings.

Why Sunflow Panels?

Resistant to weathering, moisture and pests, Sunflow panels last several years before needing replacement, hence reducing the environmental impact of having to produce, transport and install new panels.

The lightweight nature of the panels makes them easier to transport and install, also helping to reduce the environmental impact of panel production, transportation and installation.

Providing excellent insulation, the panels reduce energy loss and help to minimise heating and cooling cost.

Using Sunflow panels results in reduced carbon emissions associated with the energy consumption and operation of building, providing us with a smaller carbon footprint compared to traditional building materials.

Why Eco Anchors?

The patented Eco Anchor allow our projects to be installed with ease in remote, undulating environments, without the need for concrete or heavy excavation equipment. It works by driving the four drive rods into the ground using a pneumatic hammer – significantly more cost effective than conventional footing methods, offering savings without compromising on structural integrity or environmental impact.

The Eco Anchor system facilitates quick and straightforward installation without the need for concrete or heavy excavation equipment. This efficiency not only saves time but also reduces the environmental impact associated with traditional foundation methods.

With minimal ground surface disruption and a small footprint, the Eco Anchor system is environmentally friendly from installation to operation. It reduces material use and preserves the natural landscape, making it a sustainable choice for eco-sensitive building sites.

Installing Eco anchors is significantly more cost-effective than conventional footing methods, offering savings without compromising on structural integrity or environmental responsibility.

Using Sunflow panels results in reduced carbon emissions associated with the energy consumption and operation of building, providing us with a smaller carbon footprint compared to traditional building materials.

Why Structural Steel?

The Sunflow galvanised steel framework is extremely robust and naturally termite, mold, rust, rodent and mildew resistant. The steel frame is endlessly recyclable and 100% non-toxic.

All our products are manufactured to comply with the Building Code of Australia (BCA) standards and engineered to be capable of meeting the maximum cyclonic wind rating of Australia for any structure (Region D), and BAL 40.

All the steel components used are fully hot dip galvanised, giving our structures an unbeatable durability. Purlins are coated to Z350 and upgraded to Z450 in marine locations.

Our patented parts are transported separately and stitched together on site; using our customised installation assembly drawings.

There’s no waste because all components are cut to length with computer controlled engineering & all fixings provided in the kit.

All of our products are manufactured to comply with the Building Code of Australia (BCA) standards and engineered to be capable of meeting the maximum cyclonic wind rating of Australia for any structure (Region D), and BAL 40.

Why Lift and Brace Kits?

The Sunflow Lift & Brace kits are designed to provide strong, safe and levels bracing for the Sunflow structures, independent of the site profile.

With the help of these kits, the Sunflow system allows the client to customise their living experience, taking in previously unattainable views and expanding on their living space, regardless of the landscape limitations to conventional construction.

Our telescopic braces are available in three standard length of 1, 2 and 3m, which are further adapted and cut to the exact size required to fit the ground profile and to provide the desired elevation.

Lift and bracing kits are popular for those living in a flood zone. It protects the home from severe weather conditions, natural disasters and improper drainage.

House raising is an excellent way to not only build more space into your house but also provide a space for you to stay cool during the hot summer months.